SIZING FOR ROTATING BLADES GRIT TANKS 9. ROTATING BLADES GRIT REMOVAL 7.

Types Of Grit Chambers Horizontal Flow Aerated Vortex

Grit chambers are provided to a protect downstream moving mechanical equipment from abrasion b reduce formation of heavy deposits in pipe line and c reduce the frequency of digester cleaning.

. Theoretical length L 92 m provide 25 extra length hence length 115 m. Solution Average quantity of sewage considering sewage generation 80 of water supply is 135 x 50000 x 08 5400 m3day 00625 m3sec Maximum flow 25 x average flow 00625 x 25 0156 m3sec. Design Example for Horizontal Aerated Grit Chamber.

Solution 3 10 1. As an example of the use of Equation 2 let it be required to estimate. The value of d rr-.

The design of the effluent channel and other structures below the flume must be such that the head loss between the grit chamber and the effluent channel is not less than one-third th e difference in elevations of the upstream crest and flume floor. Parabolic weir Vortex type Circular Centrifugal force Aerated Grit Chambers Spiral movement of water. The goal of grit removal is to separate gravel and sand and other mineral materials down to a diameter between 02 and 01 mm.

Settling Velocity- is given by Stokes Law for laminar flow. The design is invariably governed by equipment manufacturers who use the DWF and peak flows as the basis. Assume SOR 1200 m3 m2day.

16 crore enrollments 15 lakhs exam registrations 4500 LC colleges 3500 MOOCs completed 60 Industry associates Explore now. FLUMES 10 Known geometry gives a predictable head discharge relationship measured upstream of the flume usually via. Example1 Design a grit chamber for population 50000 with water consumption of 135 LPCD.

Up to 24 cash back Example1 Design a grit chamber for population 50000 with water consumption of 135 LPCD. EXAMPLE GRIT CHAMBER DESIGN 6 Grit Chambers Design. Velocity is controlled by proportional weirs.

The value of d rr-. The design of the effluent channel and other structures below the flume must be such that the head loss between the grit chamber and the effluent channel is not less than one-third th e difference in elevations of the upstream. Depth 025 05 free board 025 space for grit.

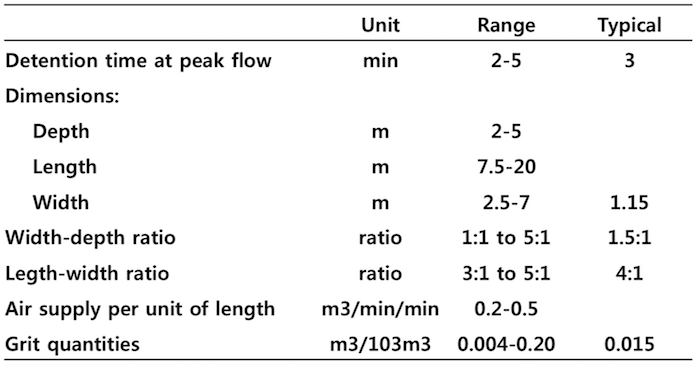

Vc 227 cmsec. Than other grit removal processes and. Aerated grit chambers are typically designed to.

Design Example of Settling Channel A suspension contains particles of grit with a diameter of 02 mm and specific gravity of 265. The design details for parshall flume to meet different discharges are provided in the CPHEEO manual 1993. EnvironmentengineeringeducationenvironmentengineeringII treatmentunitdesigns gritchamberdesignWastewater engineering is nothing but the area included in.

Vs gρp ρwdp 218µ v gG 1d 218υvs gGs 1dp 218υ Vs settling velocity dp size of particle Gs Specific Gravity 13. Non-uniform and sticky material like grit a value of about. Depth 0973 03 free board 025 space for grit accumulation Say 16 m.

GATE EnvironmentalEngineering CPCBExamDesign of Grit ChamberDesign of Sewage Treatment Plant. One design option includes a grit auger and a rake that removes and classifies grit from the grit sump. Horizontal Flow Grit Chamber The horizontal flow grit chamber is the oldest type of grit removal system.

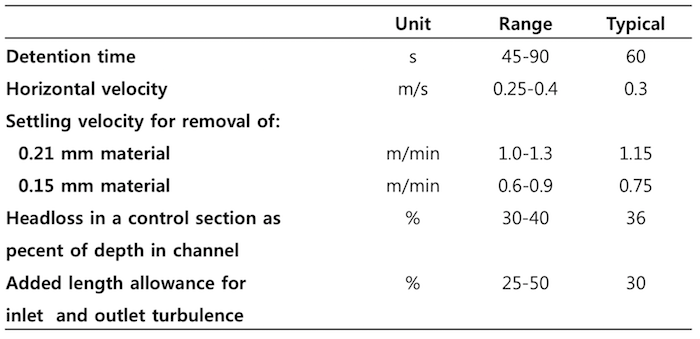

Grit is removed by maintaining a constant upstream velocity of 03 ms 1 fts. At peak hourly flow. With appropriate arrangement this.

Length width 40 m. Vortex type grit chamber 12. Alternatively Parshall flume can be placed at the end of the grit chamber Figure 154.

424 Configuration Number of Grit Chambers and Method of Degritting Grit shall be removed at the SPS to safeguard the same from causing wear to the pump. DESIGN OF GRIT CHAMBERS HORIZANTAL FLOW VORTEX TYPE AERATED Horizantal Flow 03msec horizantal velocity at all flow conditions settlement of inorganics Velocity control at the exit of chamber ex. The limiting grit chamber velocity which will avoid scour of 02 mm.

Up to 24 cash back 15. ROTATING BLADES GRIT REMOVAL WITH OIL REMOVAL 8. The limiting grit chamber velocity which will avoid scour of 02 mm.

Solution Average quantity of sewage considering sewage generation 80 of water supply is 135 x 50000 x 08 5400 m3day 00625 m3sec Maximum flow 25 x average flow 00625 x 25 0156 m3sec. Larger with a detention period of two to five minutes. 006 is probably safe for design.

In large pumping stations it pays to have two successive screens. Aerated Grit chamber 11. Find the length and the dimension of the cross section of rectangular grit chamber for treatment plant having a daily flow of 11000 m3.

GRIT CHAMBER Grit chamber is the second unit operation used in primary treatment of wastewater and it is. The settling velocity of grit particles in the range of 01 mm and 1 mm can be determined using equation 118 or its approximate empirical form of equation 1110 and these should be used in the design of grit chambers which are designed to remove particles of size 015 mm or 02 mm. For particles of this size C D 10 f 003 and 006.

Width 1 m. Maintenance and control of the aeration system. Remove particles of 70 mesh 021 mm0008 in or.

Formulation and related design parameters for Venturi flume control are presented in appendix C.

Design Of Grit Chamber Youtube

Pdf Aerated Grit Chambers Hydraulic Design Equation Semantic Scholar

Detailed Design Of Grit Chamber For Stp Download Table

Types Of Grit Chambers Horizontal Flow Aerated Vortex

0 comments

Post a Comment